Furuta Pendulum(s): Building some more

I built 6 furuta pendulums for a university controls class:

Since the original furuta pendulum was all built out of scrap I had lying around, I had to redesign pretty much everything from scratch.

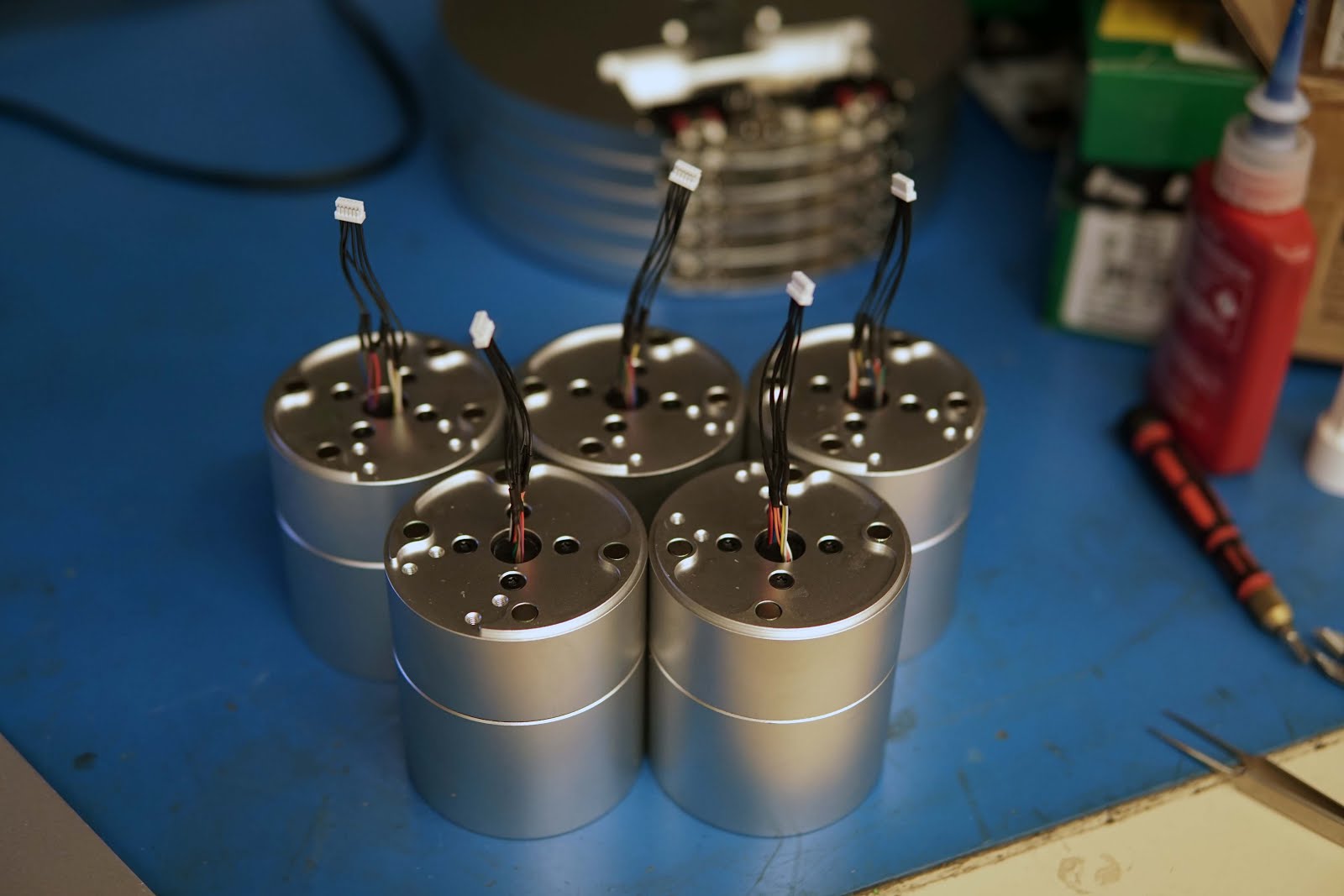

Instead of using a hand-skewed motor like the original, I used a custom-wind of a T-motor gimbal motor. These have low enough cogging torque to work pretty well:

Each motor gets a Microfit connector crimped on the leads, and a hollow shaft retaining-compounded in, for the encoder wheel to attach to:

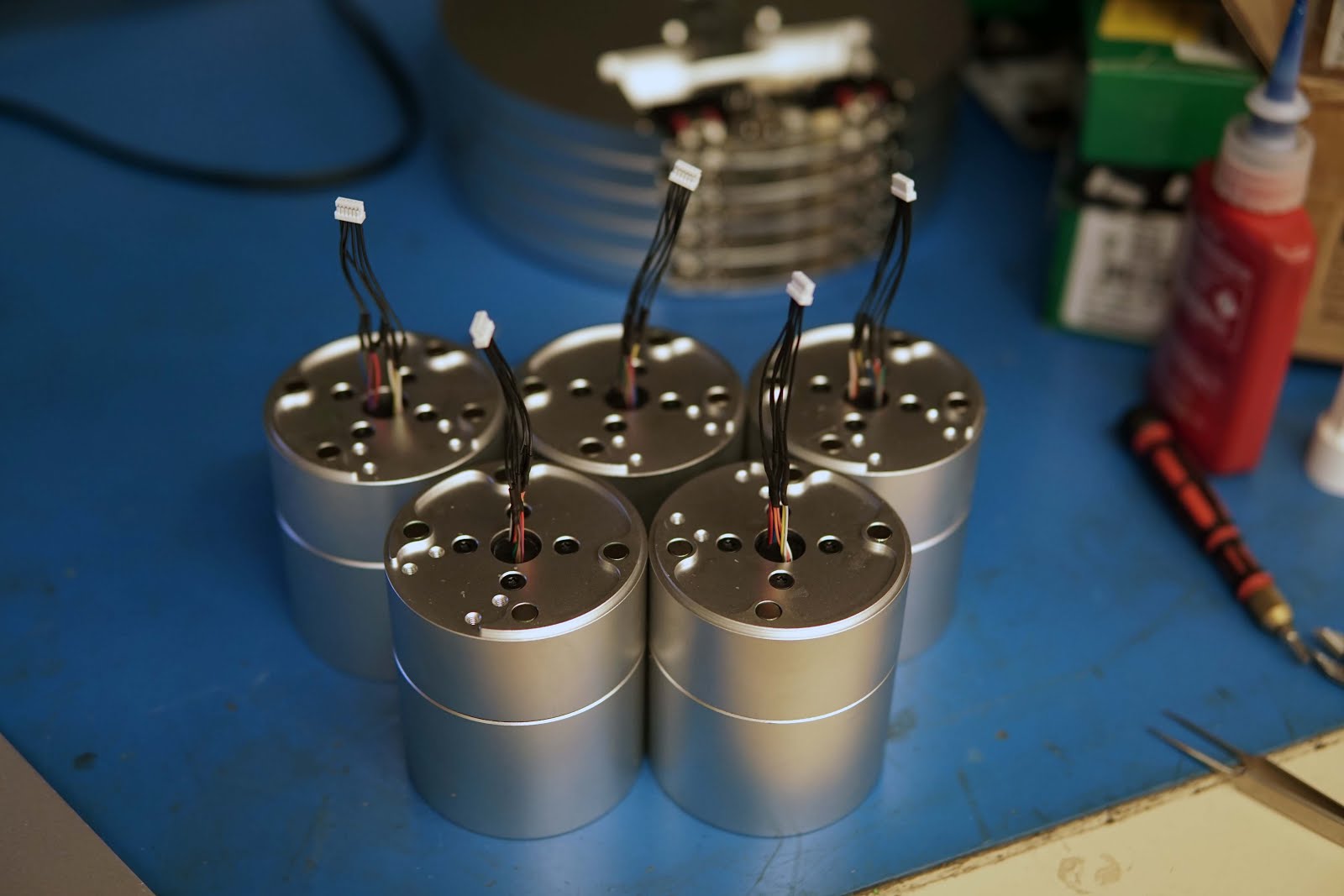

The spindle has a pair of bearings very lightly preloaded by a wavy washer, and a diametrically magnetized magnet in the back which is read by a hall encoder:

In the base is a US digital 20k count/rev optical encoder which the wires for the pendulum hall encoder pass through:

SPI to the pendulum encoder gets passed over a 12-pin slip ring, with each pin doubled-up for (hopefully) better reliability:

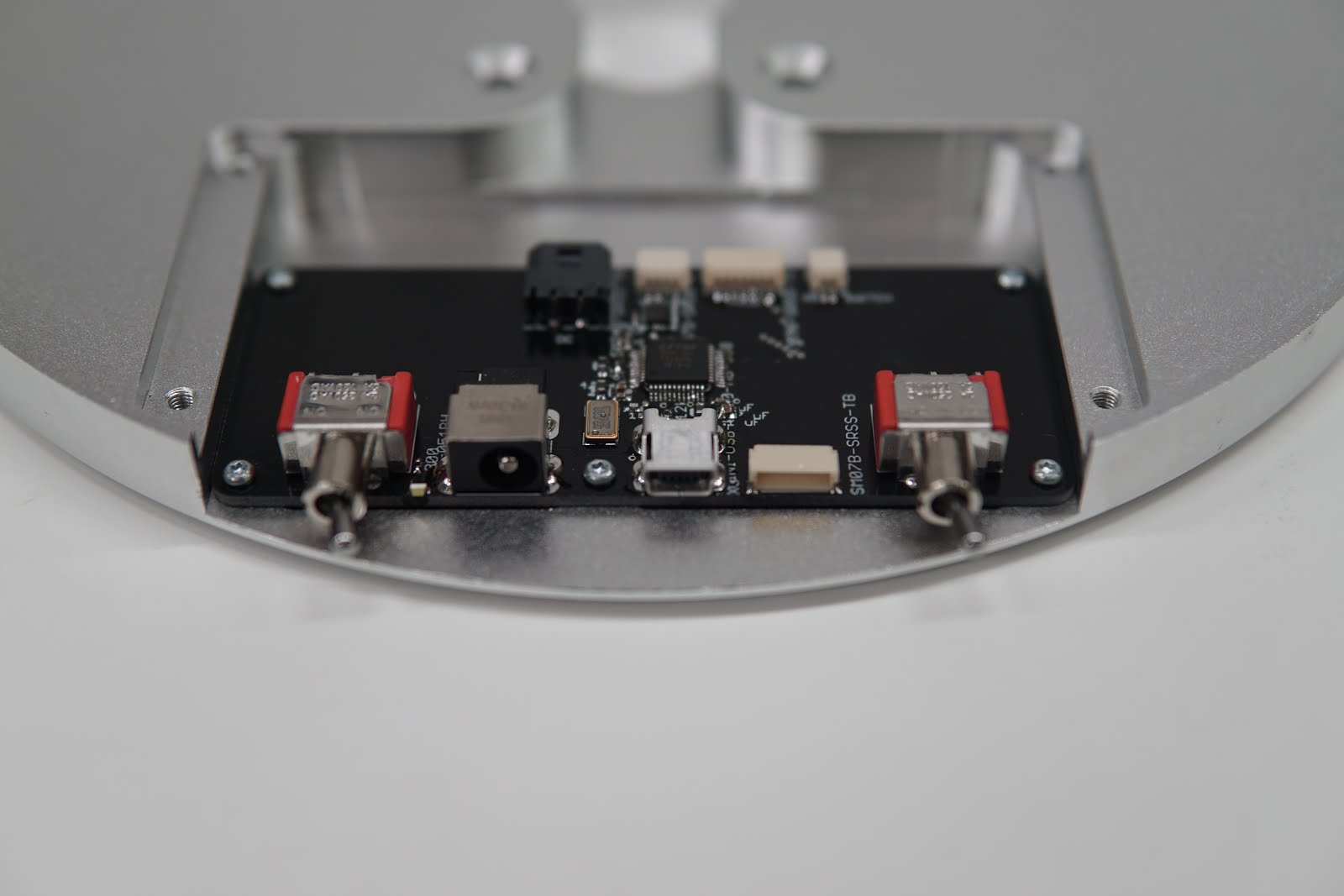

In the base there's a board with power switch, mode switch, DC input jack, USB connector for serial communication, and programming header on it. The mode switch allows the pendulum control to be done by the on-board motor controller, or by taking commands and passing back sensor outputs over serial to a computer running the controller.

Comments from Blogger