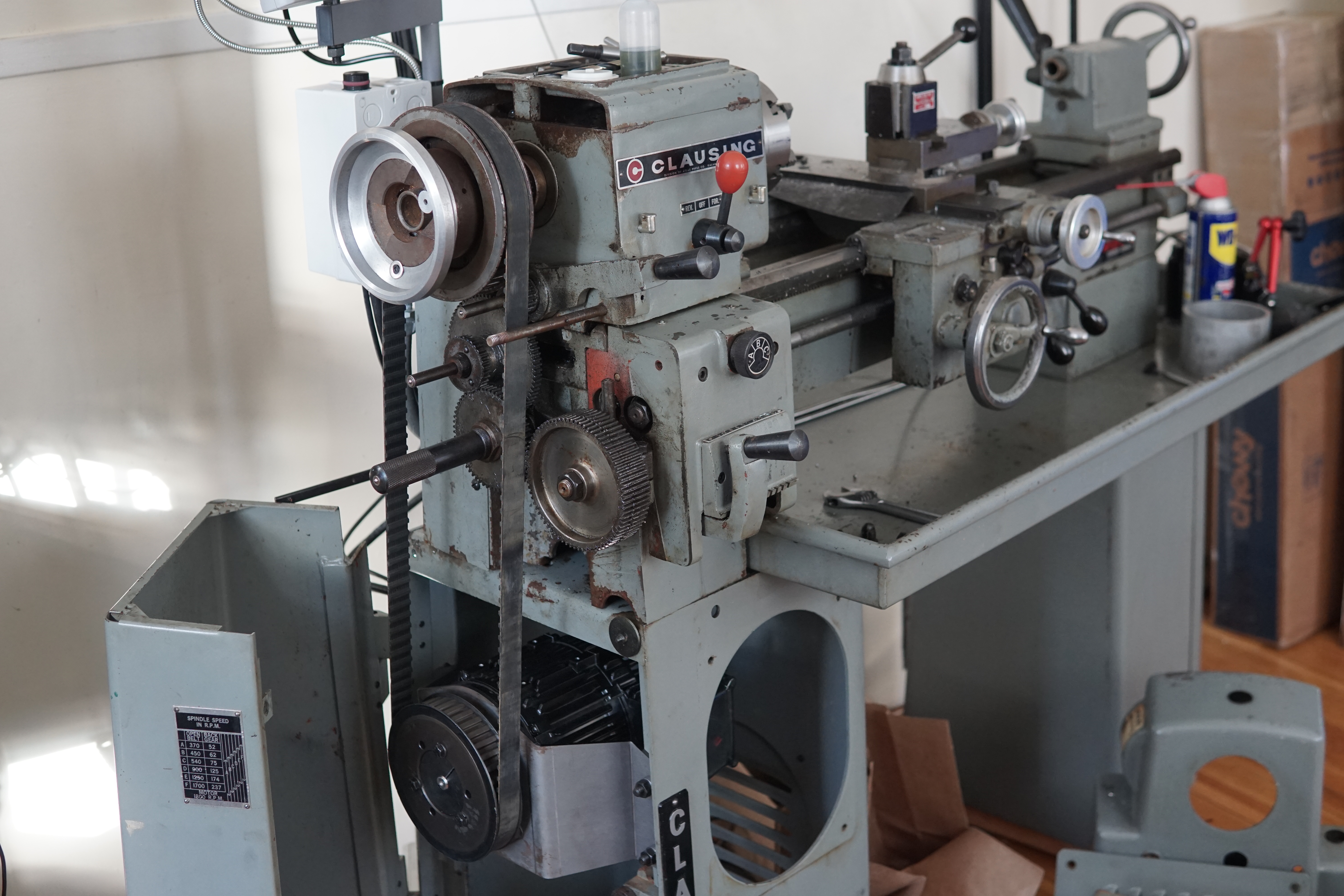

Lathe Spindle Motor Upgrade

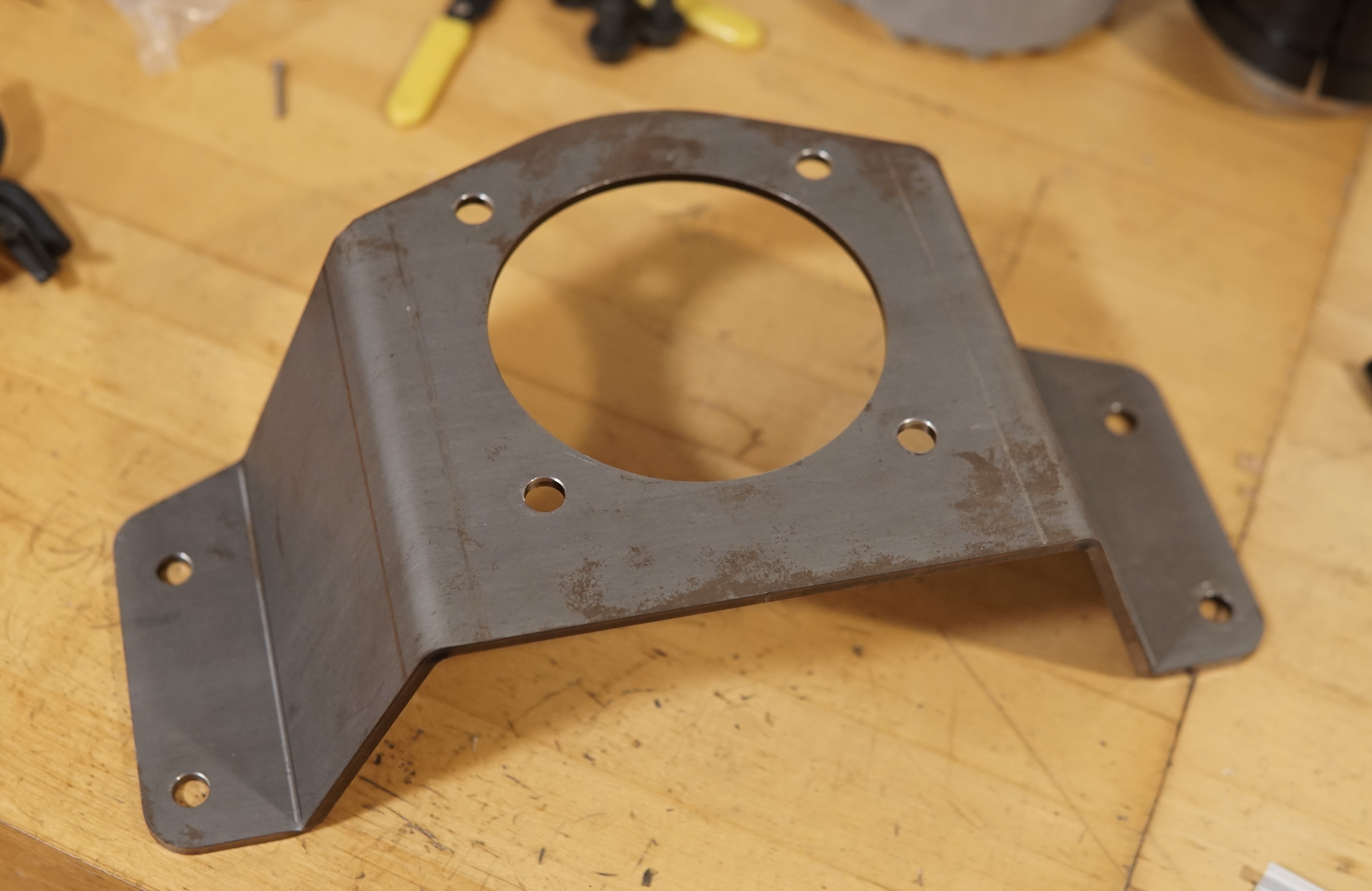

Motor bracket laser cut and bent from .188" steel by SendCutSend:

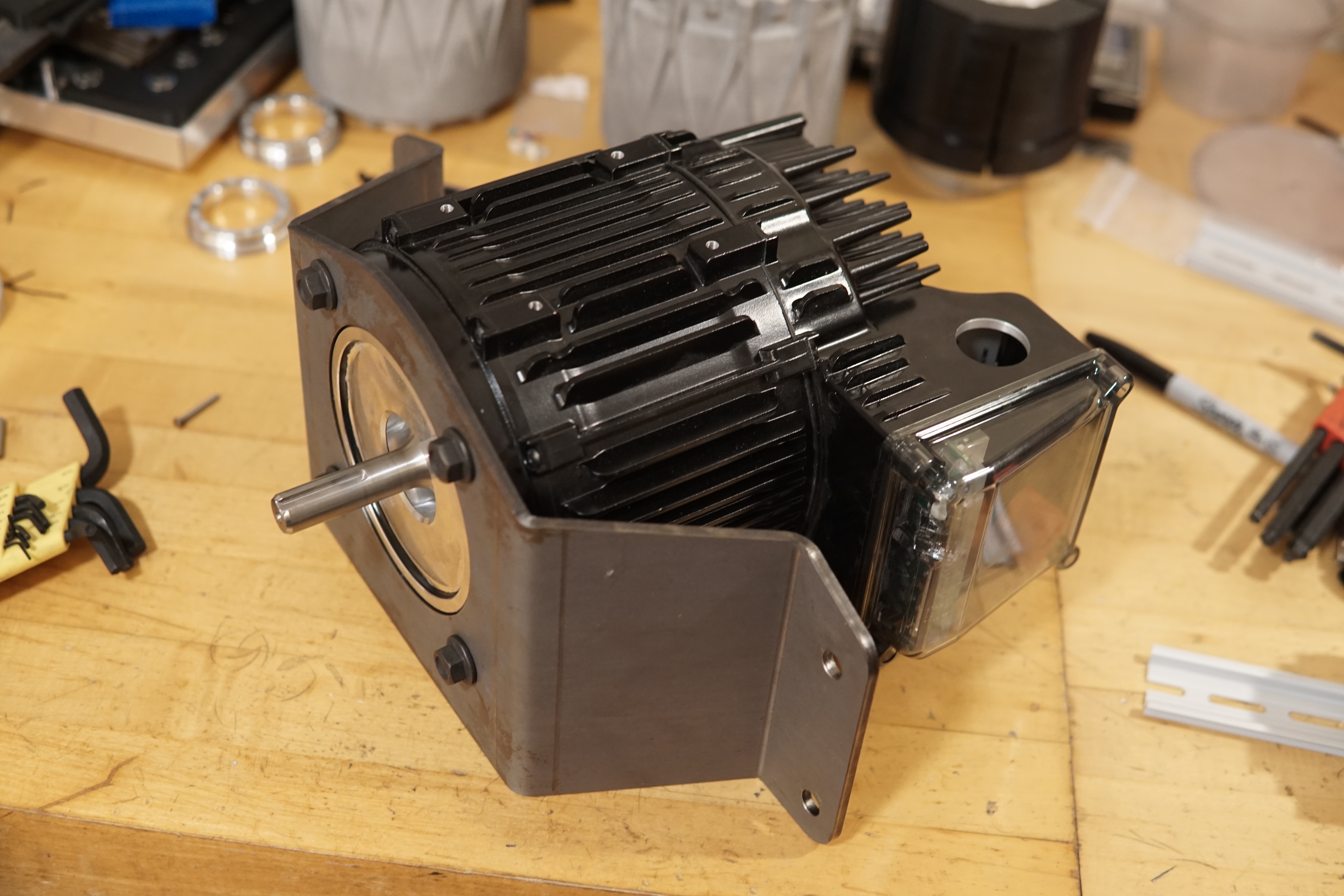

Crufted NEMA-56-size Clearpath servo motor - integrated motor drive, plugs straight into single or 3-phase mains.

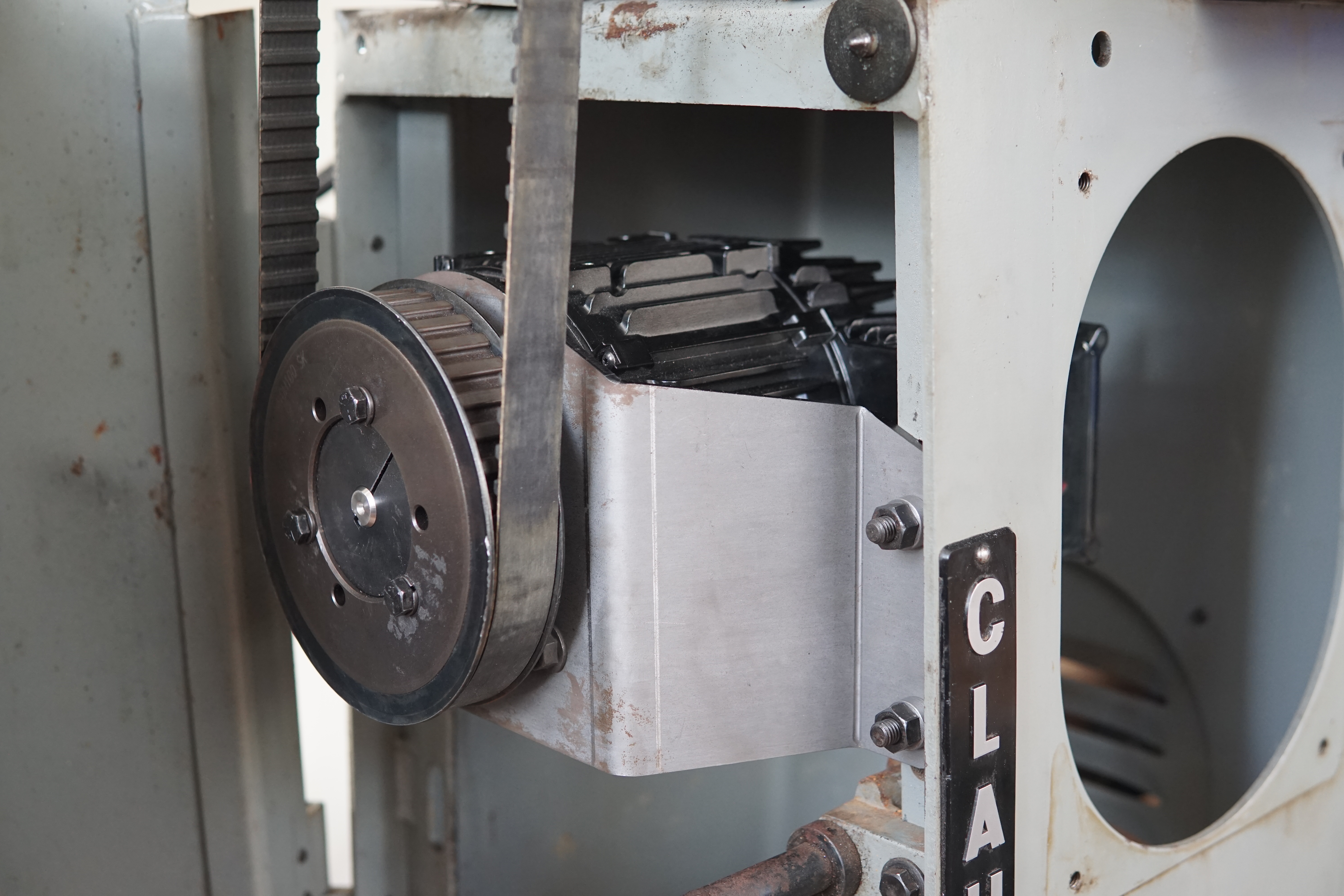

1:1 belt to the spindle:

Pile of junk being replaced:

Spin-down comparison vs the original motor from 900 RPM:

.gif)

Comments from Blogger